What is a Velocity Washer?

If you work with heavy bolted equipment, you may have heard the term Velocity Washer. So, what exactly is a Velocity Washer? In simple terms, the Velocity Washer® is a patented mechanical washer technology for industrial bolts that prevents thread galling (seizing of nuts and bolts) and enables extremely fast disassembly of bolted joints. By swapping a standard washer for a Velocity Washer, maintenance crews can eliminate seized nuts and remove bolts up to 30× faster than usual. This innovation has already seen over 100 million hours of use in the field, boosting production uptime and cutting labor costs by avoiding the delays caused by galled (stuck) nuts.

Understanding the Problem: Galling and Seized Bolts

Before diving into how the Velocity Washer works, it's important to understand the problem it solves. Galling is a form of adhesive wear (often called “cold welding”) that occurs when two metal surfaces slide against each other under high pressure. In bolted connections, galling can cause a nut and bolt to literally fuse together due to friction and heat, seizing the threads. Once a bolt is galled, it becomes extremely difficult to remove – often the nut is frozen in place and standard wrenches can’t turn it at all. In many cases, the only way to remove a galled, seized bolt is to cut or torch it off, which is a time-consuming and dangerous task. For example, on large reactor bolts, galling can force crews to spend 32–40 hours with blowtorches to free a single seized flange, leading to costly downtime (at one facility, over $250,000 per hour of lost production). Clearly, galling is a major headache in industries like petrochemical, power generation, and oil & gas – it means delays, high labor costs, safety hazards, and lost revenue.

How the Velocity Washer Solves Galling

The Velocity Washer was invented as a simple hardware solution to this galling problem. It looks similar to a thick hardened steel washer, but inside it contains an innovative stepped mechanism that allows a bolted joint to be unloaded almost instantly during loosening. In normal bolting, when you loosen a nut, you have to spin it many turns while the bolt is still under tension – that sliding under load is when galling occurs. The Velocity Washer prevents that by releasing the tension after only a slight rotation of the nut. Essentially, it acts like a quick-release for the bolt: when you start loosening, the washer “pops” and all the clamp load drops off before the threads have a chance to seize. This means the nut can then be spun off freely by hand or with a normal wrench, no fighting against galled threads.

Another way to think of the Velocity Washer is that it’s the opposite of a lock washer – instead of locking a nut in place, it helps unlock it. By limiting the motion and energy during breakout (loosening), it prevents the friction, heat, and metal-to-metal adhesion that cause galling. In summary, the Velocity Washer turns a potentially multi-hour bolt removal job into a quick, galling-free process.

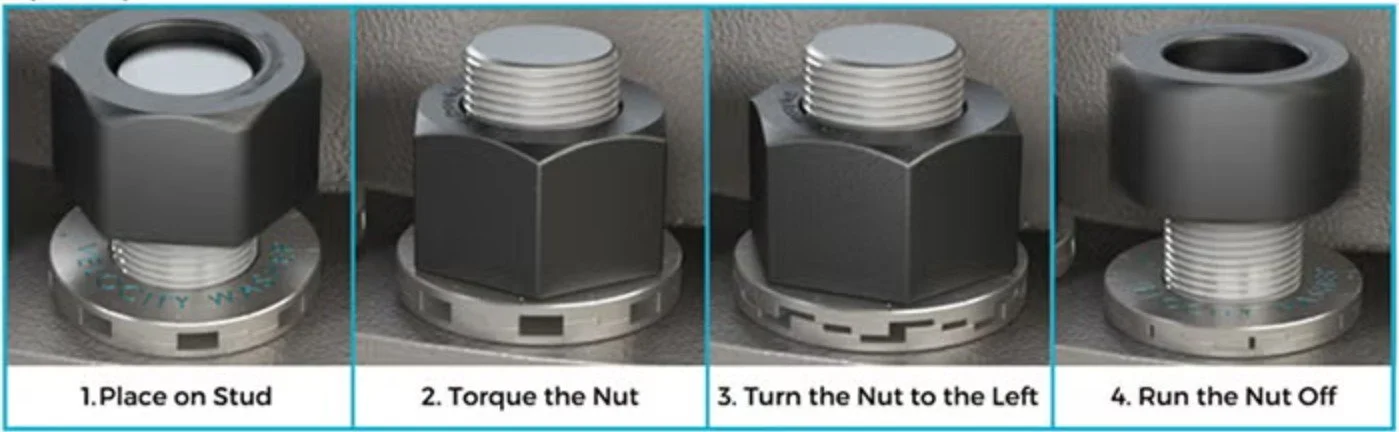

How Does the Velocity Washer Work?

The beauty of the Velocity Washer is that it installs and operates almost exactly like a normal washer. To use one, you simply place the Velocity Washer over the bolt (stud) before threading on the nut – its symmetric design means you cannot put it on in the wrong orientation, making installation foolproof. Then, you tighten the nut down using your standard torque procedures; no special tools or techniques are required at all. The engineered engravings on the Velocity Washer replicate the same friction factor (or “k-factor”) of a standard hardened washer. The Velocity Washer functions as a regular hardened washer during tightening, so you achieve the required preload on the bolt just as you normally would.

The magic is revealed when it's time to loosen the bolt. For breakout (disassembly), all you need to do is turn the nut about 12 degrees (only about one-third of a quarter-turn) to the left. After roughly this small fraction of a turn, the Velocity Washer’s internal mechanism will “pop” and release all the tension in the bolt. This audible pop indicates the bolt’s clamp load has been shed. At that point, the nut is no longer pressed tightly against the threads – it can be easily unscrewed by hand or with a standard wrench without any resistance. In practical terms, what might have taken hours before (or dangerous cutting) to undo now takes only a few seconds. The nut spins off freely, and the bolt can be removed without galling damage. Because the Velocity Washer doesn’t require any altered disassembly procedure beyond that initial small turn, workers adapt to it quickly – it’s a very simple “plug-and-play” solution for faster maintenance.

Key Benefits of the Velocity Washer

By eliminating galling and streamlining bolt removal, the Velocity Washer provides numerous benefits for industrial use. Here are some of the most important advantages:

Prevents Galling and Seizing: Velocity Washers eliminate thread galling. In fact, they have a documented 100% success rate in preventing galling across all installations globally. This means no more frozen nuts and no more destructive removal methods. Bolts come apart without damage, preserving studs and nuts for reuse and avoiding costly replacements. If you have a situation where you order new hardware after every disassembly - you can now avoid that and order only a Velocity Washer instead. This can be an excellent commercial alternative versus ordering large diameter studs.

Much Faster Maintenance: With Velocity Washers, disassembly of bolted joints can be up to 30 times faster than with traditional washers. Because a slight turn releases the tension, a task that might have taken hours (loosening dozens of large, stuck nuts) can now be done in minutes. This drastic speed improvement directly reduces equipment downtime, especially during critical maintenance outages.

Increased Uptime and Productivity: Faster bolt removal means shorter maintenance windows, which lets you bring equipment back online sooner. Simply by changing the washers, companies have added many hours of production that would have been lost. For example, one refinery gained 112 extra hours of uptime on a unit by using Velocity Washers on its reactor flange. Over multiple maintenance cycles, these time savings translate into significantly higher operational productivity and output.

Lower Labor and Tool Costs: Difficult bolting jobs often require extra manpower or specialized tools (like hydraulic nut cutters or grinders) to deal with seized nuts. Velocity Washers eliminate the need for such extreme measures, saving on labor overtime and rental of equipment. There’s no need to call in outside specialty crews to cut frozen bolts – your regular maintenance team can handle the job since the nuts won’t seize. Additionally, avoiding destructive removal means you save the cost of replacing studs and nuts, since they aren’t galled or damaged.

Improved Worker Safety: By removing the stubbornness from bolt breakout, Velocity Washers also make the work safer. In the past, workers might resort to dangerous tactics like “hot bolting” or “single stud changeout” (swapping out bolts one at a time while a flange is under pressure) or using torches and grinders on stuck bolts – all high-risk activities. With Velocity Washers, such risky procedures are unnecessary. Bolts come apart easily, no flame-cutting or prying required, which reduces the chance of injuries. Workers spend less time in hazardous conditions (for example, no prolonged use of impact guns or hydraulic torque wrenches on seized nuts), and that’s a huge safety win.

Easy to Adopt (No Special Tools or Redesign): One of the best things about Velocity Washers is that they are a drop-in replacement for standard hardened washers. They are available in a range of common bolt sizes (typically from 3/4-inch up to 5-inch diameter studs) to cover most applications. You only need to use one Velocity Washer per bolt (on the side where you loosen the nut), and it will fit anywhere a normal washer fits – there’s no need to modify your flanges or bolts to accommodate it. No special tooling or training is required to install them. In other words, adopting Velocity Washers is as simple as swapping out the washers during your next maintenance interval, and then tightening and loosening bolts the same way you always have.

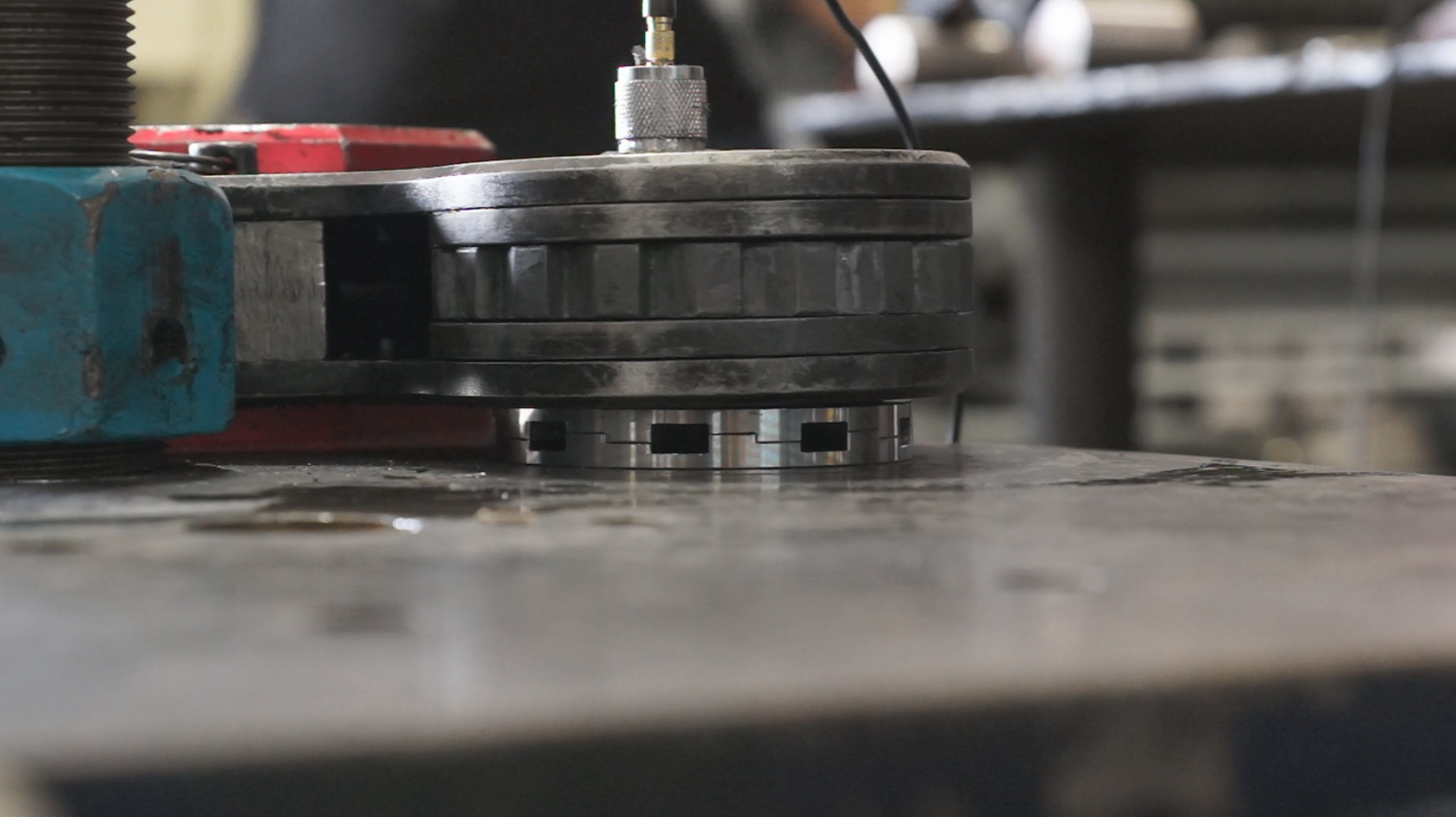

Proven Reliability and Strength: Despite its quick-release function, the Velocity Washer holds up under extreme conditions. It was engineered to meet rigorous military-grade shock and vibration standards (passing MIL-STD-167-1A and MIL-S-901D tests) – meaning vibrations won’t accidentally set it off or wear it out. In vibration tests, Velocity Washers endured over 30,000 high-G load cycles without any unintended loosening. They are made from high-strength alloy steel (e.g. heat-treated 4140 steel), so they are actually stronger than the bolts themselves – the bolt would yield before the washer fails. This gives engineers confidence that using a Velocity Washer doesn’t compromise the joint’s integrity or load capacity. The device only activates when you intentionally turn the nut for removal, and it remains stable and locked during normal operation. All these credentials show that the Velocity Washer is a robust, trustworthy solution for critical bolting tasks.

Real-World Results and Case Studies

The impact of Velocity Washers isn’t just theoretical – it’s proven in the field. Many industrial sites have reported remarkable improvements after implementing this technology on their bolted connections. Here are a couple of real examples:

Case Study 1 (Petrochemical Reactor): A global petrochemical company in the U.S. installed Velocity Washers on the large studs of a reactor head (which previously suffered from galling issues). The result was an additional 112 hours of production time saved during a maintenance turnaround. In other words, by eliminating slow, stuck-bolt removal, they shaved off nearly 5 days of downtime on that job – time that was then used for productive operation. The maintenance team was able to open and reassemble the reactor much faster than before, with all bolts coming off smoothly.

Case Study 2 (Refinery Heat Exchanger): A major oil refinery in Canada used Velocity Washers on a heat exchanger cover that had 32 large bolts (3.25″ diameter). Historically, taking this cover off was challenging – often requiring workers to torch-cut several seized nuts. With Velocity Washers in place, they achieved a 94% faster disassembly of the cover. What used to take multiple shifts of work was done in a tiny fraction of that time. Even better, there was no damage to any studs or nuts, so everything was reusable, and no “hot work” (flame cutting) was needed at all.

These kinds of results show why the Velocity Washer is gaining traction in industries where downtime is expensive. Consider the cost implications: if a refinery unit makes $20,000 worth of product per hour, saving 32 hours by not having to torch off bolts means about $640,000 in production that isn’t lost. It’s not surprising that companies like Dow, ExxonMobil, Shell, and others have started adopting this technology on their critical flanges.

Users of Velocity Washers often report almost disbelief at how well it works. One reliability engineer described that on exchangers where they “typically have to torch cut large studs,” after installing Velocity Washers “they spun off just like shown in the videos. We re-used the studs and nuts.” Another maintenance coordinator shared that normally they would budget four 10-hour shifts (40 hours) to gouge out stubborn bolts on a job, but “with the Velocity Washers it took us a bit over half a shift” (just a few hours). These testimonials underscore a common theme: what was once a laborious, multi-day chore becomes a quick and painless task after switching to Velocity Washers.

Conclusion

In summary, the Velocity Washer is a game-changing solution for anyone dealing with large bolted joints and the menace of galling. It’s a simple component swap – replace your standard washers with Velocity Washers – yet it yields outsized benefits: bolts that never seize, dramatically faster maintenance, improved safety, and reduced costs. For industrial engineers and maintenance managers, this means fewer headaches during turnarounds and more confidence that critical joints will come apart when needed. The technology takes an age-old bolting problem and solves it with elegant simplicity, using basic mechanics to prevent thread friction from ever getting out of hand.

Ultimately, the Velocity Washer exemplifies how a small innovation can have a big impact. By eliminating galling at the source, it ensures that even after years of service in harsh conditions, your nuts and bolts will come off as easily as the day they were installed. For industries where uptime is money, adopting Velocity Washers can translate into significant savings and smoother operations. It transforms bolting from a potential liability (with stuck bolts and emergency cuts) into a straightforward task. So, the next time someone asks “What is a Velocity Washer?”, you can answer: it’s the simple washer that makes bolted connections fast, reliable, and hassle-free – an innovation that truly brings velocity to bolting maintenance.

Want to learn more? Contact us using the form below: