Why Stainless Steel Experiences Thread Galling More Frequently Than Other Metals

Threaded fasteners occasionally suffer from a frustrating failure mode known as thread galling – a form of severe adhesive wear often nicknamed “cold welding.” When galling occurs, a bolt and nut can seize together as if fused into one piece of metal. Stainless steel galling is especially common; in fact, stainless fasteners are notorious for galling more often than standard steel fasteners. This article delves into the material science and mechanical reasons why stainless steel galls more frequently than other metals, covering the role of adhesive wear, work hardening, and the breakdown of protective oxide layers. We’ll also discuss engineering measures for preventing galling, and conclude with an innovative solution – the Velocity Washer – which minimizes rotational friction under load to stop galling before it starts.

What is Thread Galling? (Adhesive Wear in Metal Threads)

Galling is essentially a type of adhesive metal-to-metal wear that occurs under conditions of high friction and pressure. As two mating metal surfaces slide against each other (such as the male and female threads of a bolt and nut under load), microscopic high points (asperities) on the surfaces can catch, shear, and cold-weld together. In other words, small bits of one thread are torn off and literally stick onto the other, accumulating into lumps that further jam the threads. Once a fastener has seized from galling, it’s nearly impossible to remove without cutting or splitting the hardware. This form of wear is most often seen in stainless steel, aluminum, and titanium fasteners, whereas hardened steel bolts (especially those with protective plating like zinc) are less prone to galling - but still deal with it when under high pressures and/or temperatures. The inherent properties of stainless steel make it particularly susceptible to this adhesive wear phenomenon.

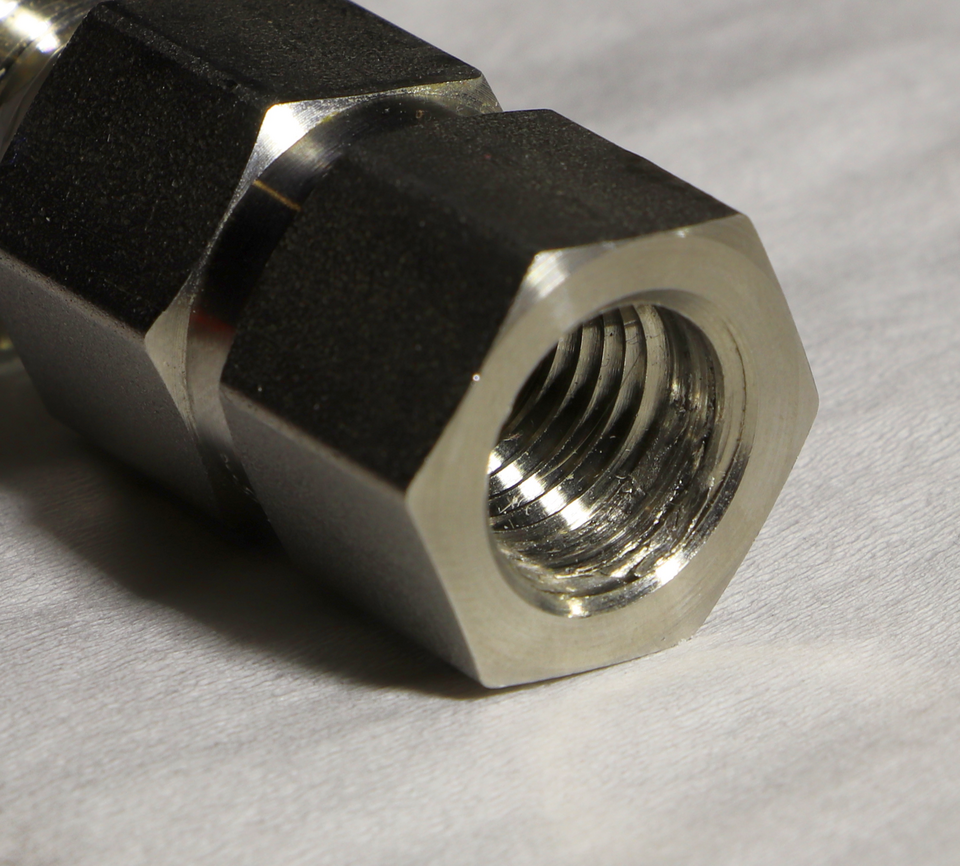

Stainless steel fitting with galled internal threads due to severe adhesive wear (note the torn, deformed thread surfaces from cold-welding)commons.wikimedia.org

Under normal low-stress conditions, metal threads can slide past each other with minimal damage. However, galling arises when the contact stress is high enough to break down surface protections. Most metals (including stainless steels) have a thin oxide film that shields the raw metal and provides a measure of lubricity. When a stainless steel nut and bolt are tightened, friction increases the interface temperature and the pressure between thread faces. At a critical point, the combination of pressure and motion disrupts the protective oxide layer, exposing bare metal on both surfaces. Now the stage is set for trouble: without the oxide film, direct metal-to-metal contact occurs, and the attractive forces between metallic atoms cause the surfaces to stick together (adhesion). As tightening continues, these sticking points rip and transfer material between the threads, creating galling “lumps” that dramatically increase friction and heat. This starts a vicious cycle of more shearing, locking, and heat generation until the threads seize completely.

In summary, thread galling (or “cold welding”) is a self-perpetuating failure caused by adhesion between sliding metal surfaces under high load. The key conditions that lead to galling are sufficient pressure to deform surface asperities, frictional heating (often from fast turning or lack of lubrication), and loss of any lubricating surface films. Stainless steel meets these conditions more readily than many other metals, as we explore next.

Why Stainless Steel is Prone to Thread Galling

Several material characteristics and mechanical factors make stainless steel fasteners more prone to thread galling than their carbon steel or plated counterparts. The propensity comes down to stainless steel’s metallurgical traits – notably its tendency for adhesive wear, the nature of its oxide layer, and how it deforms under stress. Below we break down the primary reasons why stainless steel galls more frequently:

Adhesive Wear Tendency: Stainless steels (especially austenitic grades like 304 and 316) are relatively soft and ductile metals. When two stainless steel threads interact under high load, the friction is often high due to this metal softness. The mating stainless surfaces have a natural affinity to adhere once unprotected metal touches metal. In essence, stainless-on-stainless creates perfect conditions for adhesive wear – the materials are similar and readily stick to each other, leading to that cold-welding effect. Other metals like hardened alloy steel do not gall as easily because they are harder (less prone to plastic deformation) and often dissimilar in pairings or coated, reducing the adhesion tendency.

Removal of Protective Oxide Layer: A major factor in stainless steel galling is the behavior of its oxide film. Stainless, aluminum, and titanium all form thin self-healing oxide layers for corrosion protection. This oxide normally reduces friction and prevents direct metal contact. However, under the abrasion of threading forces, these films can be scraped off at points of contact. Stainless steel’s oxide is strong in protecting against rust, but it is also thin and can shear off when two threads are pressed and sliding together. Once the oxide film is compromised, bare active stainless steel metal is exposed on both the bolt and nut. Freshly exposed stainless steel atoms have a high tendency to “grab” onto the mating surface. This is why tightening a stainless fastener can suddenly go from smooth to seized – the moment the oxide breaks, adhesion spikes and galling begins. Other metals may have oxide layers that are thicker, or (in the case of plated or coated fasteners) an entirely different surface material that provides lubrication. Stainless steel fasteners are often used unplated, so they lack that extra barrier during high-friction contact.

High Ductility and Work Hardening: Austenitic stainless steels are highly ductile – they deform rather than crack – and they also exhibit significant work hardening (strengthening of the metal from cold deformation). While high ductility means the metal can easily smear and transfer under friction, work hardening adds a twist to the galling process. As two stainless surfaces gall, the localized plastic deformation can cause the material at the contact points to harden. One might think a harder surface would resist further sticking, but in practice it can make the situation worse: the newly work-hardened fragments can bite into the mating surface instead of smoothly sliding, creating a stronger lock. In fact, surfaces that have been work-hardened during initial contact can readily bond with each other. Austenitic stainless threads often have work-hardened surface layers (from thread rolling or prior use), and once the galling initiates, those hardened micro-welded spots act like rivets binding the nut and bolt together. The result is a rapidly escalating seizure. By contrast, materials with a low work-hardening rate or higher hardness (such as hardened steel) are less prone to this kind of self-welding under stress.

Lack of Lubrication and Surface Coating: Stainless steel fasteners are frequently used in applications for corrosion resistance, and users sometimes assemble them “dry” (without grease) to avoid contamination or out of a belief that stainless-to-stainless won’t rust. Unfortunately, assembling stainless threads without lubrication greatly increases friction and galling risk. The metal surfaces have nothing to reduce shear and heat, accelerating the adhesive wear. Moreover, stainless bolts and nuts are typically the same alloy; this identical metal pairing is the worst-case scenario for galling. Using a hardened steel or plated nut on a stainless bolt significantly reduces galling tendency (the harder, smoother zinc-plated nut is less likely to seize). The fact that stainless hardware is often all-stainless (for uniform corrosion resistance) means we often have two soft, similar metals grinding against each other with no sacrificial coating – a perfect recipe for galling. Fine thread pitches and any roughness or dirt will further exacerbate the issue by increasing the contact area and friction. It’s no surprise that galling is sometimes called “stainless steel seizing” – stainless bolts are simply more vulnerable to this failure mode than carbon steel ones.

In summary, stainless steel galls more readily because it is a soft, highly adhesive metal protected by a thin oxide that fails under load. Once that oxide is gone, stainless’s ductile nature and work-hardening behavior foster a rapid weld-up of the threads. Other metals (like quenched & tempered steels, or those with anti-galling coatings) either maintain a protective surface or don’t share stainless’s tendency to cold-weld, so they experience galling far less frequently. As one fastener supplier notes, stainless, aluminum and titanium fasteners are the usual suspects for thread galling, whereas hardened steel bolts rarely have this problem.

How to Prevent Thread Galling (Best Practices)

Fortunately, galling can be mitigated through both design choices and proper assembly practices. Engineers and technicians in industry routinely employ the following strategies to prevent thread galling in stainless steel joints:

Lubricate Threads: Adequate lubrication is one of the most effective defenses against galling. Applying a high-quality anti-seize compound or thread lubricant (containing solids like molybdenum disulfide, graphite, or PTFE) provides a film that separates the metal surfaces. This reduces the friction coefficient and dissipates heat, so the conditions for adhesion are minimized. Lubricants also help fill in microscopic gaps, preventing metal asperities from locking together. It’s widely recommended (and even specified in standards like ASME PCC-1) to lubricate stainless steel fasteners during assembly to control friction and achieve proper preload without seizing.

Use Different Materials or Hard Coatings: Changing one component of the fastener pair to a dissimilar or harder material can prevent galling. For example, pairing a stainless steel bolt with a hardened steel nut (especially zinc-plated) or using different grades of stainless for nut and bolt will reduce the tendency to gall. Galling is worst when both thread materials are the same alloy. Engineers sometimes select galling-resistant alloys such as Nitronic 60 or apply surface treatments like silver plating, nitride hardening, or low-friction coatings (Xylan®, PTFE) to fasteners that would otherwise gall. These measures either increase surface hardness or introduce a lubricious barrier, preventing metal adhesion. In short, mix up the materials or add a coating whenever possible if using stainless-on-stainless is causing issues.

Slow Down Installation: High-speed tightening (such as using impact guns or power drivers) generates rapid frictional heating. With stainless fasteners, this can quickly overheat the interface and destroy the oxide film before heat can dissipate. To avoid this, always tighten stainless steel nuts and bolts slowly and steadily, especially for the final torque. Manufacturers advise against power tools for galling-prone materials; hand tightening or controlled low-speed tools are preferable. By slowing the nut’s rotation, you give any frictional heat more time to escape, preventing local hot spots that could trigger galling. If a nut begins to bind, it’s wise to stop, let it cool, and then back it off to inspect – continuing to wrench on a heating, binding stainless nut is a sure way to seize it.

Ensure Clean, Smooth Threads: Damaged or dirty threads create extra friction and points of concentrated contact. Always inspect stainless fasteners for burrs, nicks, or debris before use. A nut should run down a bolt easily by hand; if it doesn’t, forcing it under high torque can induce galling on the rough spots. Use rolled threads when possible – rolled threads have a harder, smoother surface finish than cut threads, which helps reduce galling tendency. Also prefer coarse threads over fine threads in galling-prone applications: coarse threads have deeper profiles and less total contact area, which is a bit more forgiving if conditions aren’t perfect.

By implementing the above practices – lubricating, mixing materials or coatings, controlling speed, and keeping threads in good condition – engineers can greatly reduce the incidence of galling. However, even with all precautions, galling can still occasionally rear its head during disassembly of long-served bolts or in critical, large-size fasteners. For such cases, innovative solutions have been developed to eliminate galling entirely.

Conclusion: Eliminating Galling with the Velocity Washer Solution

One cutting-edge tool to virtually eliminate thread galling in stainless steel bolted joints is the Velocity Washer. The Velocity Washer is a patented anti-galling washer that prevents the conditions that cause galling in the first place. It is installed under the nut like a standard washer and cleverly minimizes rotational friction under load by rapidly relieving the clamping force on the threads during breakout (loosening) of the fastener. In practice, when you go to loosen the nut, the Velocity Washer will “pop” after only a small fraction of a turn (about 12° of rotation), instantly releasing the compressive load on the threads. With the bolt load removed, the nut can spin freely off without grinding under high pressure – the nut simply is not allowed to turn long enough under load for galling energy to build up. By removing thread pressure at the critical moment, the Velocity Washer ensures the adhesive wear mechanism never even gets started. Field installations have shown a 100% success rate in preventing galling using this method.

In summary, stainless steel’s tendency to gall comes down to its material properties (softness, ductility, rapid work hardening) and the breakdown of its protective oxide under friction. These factors result in adhesive wear that can seize threads and halt operations. Understanding these causes allows engineers to combat stainless steel thread galling through better practices and design – from lubrication and material selection to slow tightening speeds. And for a practical final safeguard, technologies like the Velocity Washer can be employed to stop galling at its root by removing harmful friction under load. By addressing both the material science and the mechanics of tightening, we can keep our stainless steel nuts and bolts turning smoothly and prevent galling before it happens.

_____

Disclaimer:

Portions of this article were generated with the assistance of ChatGPT, a large language model developed by OpenAI. The content is provided for informational purposes only and does not constitute professional, legal, financial, or academic advice. The views expressed do not necessarily reflect those of the author, and readers are encouraged to independently verify any information presented.

The AI-generated content has been reviewed and edited for clarity and accuracy where appropriate.