From Shutdown to Startup: How Bolt Failure Impacts Plant Turnarounds

Plant turnarounds – those planned shutdowns for maintenance and inspections – are high-stakes events in the oil, gas, and petrochemical industries. Every day of downtime is carefully scheduled and extremely costly. Yet, despite meticulous planning, something as small as a bolt can throw an entire turnaround off track. Picture a refinery maintenance crew struggling with a seized flange bolt on a critical heat exchanger: the clock is ticking, the startup date is looming, and one stubborn fastener threatens to cascade into extended downtime and soaring costs. Bolt failures might seem like a minor detail, but in the context of major industrial turnarounds, they can have outsized impacts on cost, safety, and schedule. This post dives into the technical reasons bolts fail, the domino-effect consequences when they do, and how emerging solutions like the Velocity Washer are helping engineers go from shutdown to startup more smoothly and safely.

The Bolting Challenge in Turnarounds

During a turnaround, thousands of bolted joints must be opened, serviced, and reassembled. Bolts on pressure vessels, heat exchangers, piping flanges, and valves are often handling extreme pressures and temperatures in service. Over time, these fasteners are subjected to stress, heat, corrosion, and sometimes improper maintenance practices. When the plant is shut down and maintenance begins, bolts that have endured these conditions don’t always cooperate. A bolt that won’t loosen – or worse, breaks or gets damaged during removal – can transform a straightforward maintenance task into a major schedule headache.

Even outside of planned outages, bolts can fail during normal operations (an unplanned downtime scenario), causing emergency shutdowns. Whether during a scheduled turnaround or an unexpected outage, bolting problems are a critical concern for maintenance managers. Understanding why bolts fail and how that failure ripples through a plant’s operations is key to preventing small issues from becoming big problems.

Common Bolt Failure Mechanisms

Not all bolt failures are alike. Below are some of the most common bolting failure mechanisms encountered in industrial facilities, and why they happen:

Thread Galling (Seizing): Galling is a form of severe friction between mating threads that causes them to fuse together. It’s often likened to a “cold welding” of the bolt to the nut. This typically occurs during tightening or loosening under high load, especially with stainless steel or other alloy bolts. A galled bolt will suddenly seize and refuse to turn further. At that point, removal becomes extremely difficult or impossible without cutting the bolt or splitting the nut. Galling often takes maintenance teams by surprise – a bolt that was tightening fine one second may lock up the next. The end result is usually a ruined bolt and nut, unplanned cutting or grinding work, and schedule time lost. Galling is a notorious culprit in turnarounds because it frequently occurs right when you’re trying to open equipment for maintenance. A crew might spend hours on a single seized nut that should have come off in minutes.

Overtightening: While it’s crucial to apply proper torque to bolts, excessive torque or improper bolting techniques can lead to failures. Overtightening a bolt can stretch its threads or even yield (permanently deform) the bolt shank. In some cases, the bolt may break outright during tightening. Even if it doesn’t snap immediately, an overtorqued bolt is compromised – the stretched threads can make future removal extremely difficult, and the bolt may not retain the intended clamping force on the joint. Moreover, overtightening can crush gaskets or distort flange faces, leading to flange leakage when the system is pressurized. In essence, a well-intentioned but overzealous tightening can undermine the very integrity of the joint. During turnarounds, if workers are not using calibrated tools or proper procedures, they risk damaging bolts and flanges by overtorquing, setting the stage for problems either at startup or during the next disassembly.

Corrosion and Degradation: Bolts in petrochemical and refining environments often face harsh conditions: moisture, chemicals, salt (in coastal plants), and high-temperature processes can all contribute to corrosion. Over years in service, a carbon steel stud might rust to the point of losing significant cross-sectional area (weakening the bolt) or bonding the nut to the threads. Corroded bolts tend to seize up; when maintenance begins, they may snap when torque is applied, or simply refuse to turn due to rust buildup. Even high-grade alloy bolts can suffer stress corrosion cracking or hydrogen embrittlement in certain environments, leading to unexpected fractures. Corrosion not only makes disassembly difficult, it also means the bolt might not be providing the clamp load it should, which can result in leaks or failures under pressure. Teams often plan to replace heavily corroded fasteners during turnarounds, but finding out a critical bolt is essentially “frozen” in place can still be a nasty surprise that delays work.

(Other failure modes like fatigue, vibration-induced loosening, or damaged bolt heads can occur as well, but galling, overtightening, and corrosion are among the most frequently encountered in turnaround scenarios.)

Cascading Consequences of Bolt Failures

When a bolt fails or cannot be removed, the consequences go far beyond that single fastener. Bolted joints are fundamental to containing fluids and pressure, so any compromise can trigger a chain reaction of issues. Let’s examine how one bolting problem can cascade into larger troubles:

Flange Leaks and Process Loss: A loss of bolt tension or a broken stud on a flange can create a leak path for whatever fluid is inside. Even one missing or ineffective bolt in a pressurized joint may lead to a gasket leak. In an operational plant, a minor leak can quickly escalate – if flammable or toxic chemicals escape, it poses immediate danger to personnel and can ignite or cause hazardous exposure. Even in a turnaround setting, a leak during pressure testing or startup means the maintenance was not successful and the equipment must be opened up again. A single leaking flange due to a bolting issue can keep an entire unit offline, delaying the startup until it's fixed.

Delayed Restarts: Turnaround schedules are orchestrated with precision. A stuck or broken bolt can halt a critical path activity, such as opening a distillation column or resealing a reactor, which in turn holds up all downstream tasks. For example, imagine a team trying to remove a manway cover on a process vessel: if half the bolts come off normally but a few are seized (galling or corrosion) and require cutting and drilling out, that task’s duration might jump from a few hours to a day or more. This delay ripples through the schedule – inspection crews have to wait longer to get inside the vessel, any fixes inside are pushed out, and the entire turnaround’s completion might slip. In worst cases, the plant’s startup is delayed by days, during which production is zero but labor and overhead costs continue to accrue. The phrase “time is money” is painfully true during turnarounds. What starts as one bad bolt can end up extending the shutdown, affecting product delivery commitments and incurring substantial opportunity costs.

Unplanned Interventions: Bolt failures often force maintenance teams to take unplanned actions that carry their own risks and costs. If a nut won’t budge with a standard wrench, workers may escalate to cheater bars (increasing risk of injury as they apply high force) or resort to hot work – using a torch to heat or cut the bolt. Cutting out a seized bolt is time-consuming and introduces safety hazards (fire risk from flames, the need for hot work permits, etc.). If a stud breaks off in a threaded hole, technicians then face the tedious task of drilling out the remnants or using extractors, and possibly re-tapping holes or replacing entire flange components. All this unplanned work was not on the original schedule or budget. It also diverts skilled personnel away from other tasks. In some cases, specialized contractors might be called in to machine out broken bolts or perform on-site flange repairs, incurring extra cost. Furthermore, whenever the plan changes on the fly, there’s greater potential for mistakes or omissions, which themselves can have cascading effects (for instance, a rushed job to drill out a bolt could damage the flange face, causing sealing issues later). In summary, one bolt issue can spawn multiple unplanned jobs, each with its own challenges.

Integrity Concerns: When a bolt fails, it raises a red flag about the integrity of that joint and potentially similar joints. If one bolt on a heat exchanger was found severely corroded or cracked, engineers must question whether other bolts in similar service are at risk. This can lead to additional inspections or even a decision to replace all bolts on a critical flange as a precaution. That means more work during the turnaround that wasn’t initially anticipated. In an unplanned downtime scenario (say a bolt snapped and caused a leak while running), there will be a root cause investigation. Often, the response isn’t limited to fixing the one bolt; the team might decide to inspect a whole circuit of equipment for similar issues before safely restarting. This prudent approach improves safety and reliability, but it again means more time and resources spent, extending the downtime impact from that initial failure.

In essence, bolt failures have a way of multiplying problems. A single point of weakness in a bolted joint can lead to leaks, which then lead to shutdowns, delays, and a frenzy of corrective actions. For maintenance and reliability professionals, preventing these cascading consequences is a top priority – and it’s why bolting has become a significant focus in turnaround planning.

Safety Implications: Bolts and Workplace Hazards

Beyond schedule and cost, bolt failures are a serious safety concern in maintenance operations and plant uptime. Consider the safety dimensions of a bolting issue:

Hazardous Leaks and Explosions: As mentioned, a leaking flange due to a loose or failed bolt can release dangerous substances. High-pressure hydrocarbon leaks can create a vapor cloud that’s one spark away from a fire or explosion. In petrochemical plants, even a small release of toxic gas or corrosive liquid can endanger workers and trigger evacuations. History has shown that some industrial accidents trace back to something as simple as a gasket leak on a bolted connection. Thus, one failed bolt can compromise the safety of the entire facility if it leads to an uncontrolled release. Safety systems and protocols (like gas detectors and emergency shutdown systems) might mitigate the immediate danger, but the best case scenario still involves halting operations and initiating emergency response measures.

Injury Risks During Maintenance: Handling stubborn or failed bolts can put workers in harm’s way. When a technician struggles with a frozen nut, there’s a risk of the wrench slipping or the sudden break-loose of the bolt leading to a loss of balance. Sprained wrists, smashed knuckles, or even falls from heights can occur during the brute-force removal of stuck fasteners. In one real example, a mechanic applying heavy force to a seized bolt suddenly had the tool give way, causing him to fall against nearby equipment and crack a rib. In another, workers using a wrench and cheater bar on a corroded flange bolt had the bar slip, resulting in a hand injury. These incidents underscore that muscling a stuck bolt is not just a schedule problem, but a safety problem.

Hot Work and Fire Hazards: If cutting torches or angle grinders are used to remove bolts, the work area must be treated as a hot-work site. That means clearing flammable materials, obtaining permits, stationing fire watches, and ensuring everyone wears appropriate PPE. Even with precautions, introducing open flames or sparks in an industrial environment carries risk. There’s the direct fire hazard, and also the health hazard of fumes from heating or cutting metal (coatings on bolts can release toxic smoke, for example). Plus, hot work on a large scale can be exhausting for crews – think of spending hours under a vessel, torch-cutting dozens of seized nuts, all while managing heavy gear and protective equipment. The fatigue and stress can in turn increase the chance of accidents.

Compromised Startup Safety: A bolt that was overtightened or not replaced when it should have been can become the weak link when the plant starts back up. If a bolt fails during the pressurization of a system on startup, it might result in a sudden, violent release. Startups are moments of high energy – pumps are cranking up, fluids are flowing, pressure is climbing – so that’s when any bolting weaknesses will reveal themselves, often dramatically. The safest outcome of a bolt failure on startup is that a pressure test is failed and everything is brought down in a controlled way; the worst outcome could be an on-stream rupture. Therefore, ensuring bolted joints are sound before returning to operation isn’t just a reliability concern, it’s a fundamental safety requirement.

In summary, bolt failures endanger personnel both directly (through handling and removal during maintenance) and indirectly (through leaks and equipment failure in operation). Maintenance managers and EHS professionals pay close attention to bolting issues to protect their crews and the facility. Every additional hour spent wrestling a bolt is extra exposure to hazards, so eliminating bolting problems has a clear safety payoff.

Financial and Operational Costs of Bolt Failures

From a business perspective, the costs associated with bolting failures during turnarounds or unplanned downtime can be tremendous. Some of the major financial and operational impacts include:

Extended Downtime Costs: Downtime is often measured in lost production. In a refinery or chemical plant, being offline means you’re not producing product to sell. Depending on the size of the operation, a single lost day of production can cost anywhere from tens of thousands to millions of dollars in revenue. When bolt problems extend a turnaround by a day or two, that’s essentially money left on the table. Unplanned downtime can be even worse – a surprise shutdown due to a bolt-related leak means sudden losses that were not budgeted. For example, if a critical compressor is taken offline because a small bolted seal blew out, the throughput drop might cost a fortune until it’s fixed. These direct losses in revenue are usually the biggest chunk of cost, and they mount quickly with each hour of delay.

Labor and Repair Expenses: Bolt failures drive up maintenance costs. Extra labor is one obvious factor – if a crew has to spend six hours cutting out a single bolt, that’s six hours of wages (often at overtime rates during a turnaround) spent on non-productive rework. Multiplied over dozens of stubborn bolts, the labor costs climb significantly. There may also be a need for specialized services: for instance, hiring a contractor with portable machining tools to drill out broken studs, or bringing in additional riggers and equipment to handle a delayed heavy lift after a flange issue is resolved. New parts add cost as well. Galled or damaged nuts and bolts must be scrapped and replaced with new ones; if a flange or valve is damaged in the process, that component might need repair or replacement. Each unexpected issue introduces more line items to the turnaround budget.

Logistical and Supply Chain Impacts: In tightly scheduled turnarounds, critical path delays can trigger contractual penalties or expedited shipping costs. If a bolt problem on a major unit threatens to delay product delivery commitments, a company might have to arrange alternate supply (at higher cost) to customers or incur fines for late delivery. There are cases where refineries have had to pay to import products because their own unit didn’t start up on time. Additionally, if unexpected bolting issues mean you suddenly need new studs or gaskets that weren’t in the initial plan, you might have to rush-order these parts. Expedited logistics for parts (overnight shipping, special courier, etc.) inflate costs.

Opportunity Cost of Resources: A plant turnaround is a resource-intensive event. Hundreds or thousands of workers, contractors, and pieces of equipment are coordinated like an army. When a small problem like a bolt seizure happens, it can cause idle time in other areas. Think of a scenario where an entire maintenance team is waiting because one flange on a common pipe isn’t open yet due to a stuck bolt – other connected work can’t proceed, meaning you’re paying people to wait. This inefficiency is a hidden cost. Moreover, management time and attention get diverted to troubleshooting the issue, taking focus away from other critical activities. In sum, bolt failures reduce the overall efficiency of a turnaround, which equates to higher cost for the same outcome.

Lifecycle and Reliability Costs: There’s also a longer-term financial aspect. If bolts are not properly handled and end up causing slight flange damage or improper reassembly, you might get leaks or failures sooner than the next planned maintenance. That could force another downtime event earlier than expected, which is a huge cost. Thus, any compromise made during a frantic fix (say, not perfectly re-facing a flange after drilling out a bolt, or reusing a questionable bolt because time was short) can sow the seeds of future problems. Reliability engineers know that short-term fixes can lead to long-term expenses. Therefore, consistent investment in good bolting practices and quality repairs is justified by avoiding those future unplanned outages.

When presenting these issues to upper management, maintenance managers often translate bolting issues into dollar figures. It quickly becomes clear that spending a bit more on prevention or better tools is trivial compared to the potential losses. A single seized bolt that adds 12 hours to a critical path can mean a cascade of costs far exceeding the price of any bolt or special washer. This is why the industry is eager for solutions that can de-risk bolting operations during turnarounds.

Turnaround Delays and Downtime: The Schedule Impact

Time is the defining metric of turnaround success. A plant that doesn’t start back up on schedule can miss production targets, market opportunities, and even risk its reputation for reliability. Here’s how bolt failures specifically affect turnaround duration and downtime:

Critical Path Disruption: Every turnaround has a “critical path” – the sequence of tasks that determines the minimum duration of the entire project. Often this includes opening, servicing, and closing large pieces of equipment like reactors, columns, or exchangers. Bolts are literally at the start and end of those tasks (you have to unbolt to open, and bolt up to close). If any of those critical path joints hits a snag (like a frozen nut that slows opening, or trouble achieving a tight re-bolting during closing), the critical path gets longer. Unlike less critical tasks, a delay here cannot be recovered by doing something else in parallel; it directly pushes the entire turnaround finish date. Turnaround planners therefore worry a lot about any activity that involves large numbers of bolts, because the potential for variability is high. They might build in some contingency time, but unexpected bolt issues can eat through that buffer quickly.

Sequential Task Delays: Industrial maintenance is often a choreographed sequence. For example, you can’t remove a tower’s internals for inspection until the manway is unbolted and opened. You can’t perform a pressure test until everything is bolted up and tight. One slow bolt can stall the next task in line. This sequential nature means bolt problems have a multiplier effect on schedule. A task scheduled for 8 hours that runs into a 4-hour bolt removal problem doesn’t just finish 4 hours late; it also starts subsequent tasks 4 hours late, which might bump into workforce shift changes or lost daylight for certain jobs. In complex turnarounds, these schedule dominos can be felt plant-wide.

Unplanned Downtime Length: In cases of a forced shutdown (outside of planned maintenance), the duration of downtime often comes down to how quickly a repair can be executed. If the root cause is a leaking flange or damaged bolted joint, the timeline to restart will depend on extracting damaged bolts, getting replacement parts, and safely re-tightening everything. Bolt failures can turn what might have been a one-shift fix into multiple days of work. For instance, swapping a faulty valve could be a routine 5-hour job, but if the valve’s flange bolts are all frozen and three of them snap, you might spend two days on extraction and rethreading operations. This prolongs the outage and increases production loss. Unplanned events also tend to happen at the worst times (nights, weekends, at reduced staffing), which can further slow the response. Thus, a small bolt issue can dictate how long a unit remains down, because you simply cannot repressurize until that joint is fully restored and verified.

Impact on Overall Turnaround Quality: Sometimes in the rush to make up lost time from bolt troubles, shortcuts might be taken – for example, skipping a planned step like using a torque wrench due to time pressure once the bolts are finally free. This can compromise the quality of the work and lead to discoveries of leaks or loose bolts during the startup pressure tests. If a startup is aborted due to a leaking flange that wasn’t properly tightened (perhaps because earlier delays put the team behind and they rushed the closure), the downtime extends even further. Therefore, bolting issues not only delay the schedule directly, but they also can indirectly cause rework that lengthens the turnaround if not managed carefully.

In summary, efficient bolt handling is crucial to keeping turnarounds on schedule. Turnaround managers often treat bolting activities as potential bottlenecks and seek ways to make them more reliable and predictable. Reducing variability in bolt removal and tightening directly translates to more confidence in meeting the startup deadline.

Emerging Technologies: A Faster, Safer Way with the Velocity Washer

Given the significant impacts bolt failures can have, the industry has been actively searching for technologies to improve bolting reliability and efficiency. One of the most promising innovations in recent years is the Velocity Washer, a patented solution designed specifically to tackle problems like galling and slow bolt removal. This technology is changing how maintenance teams approach critical bolted joints:

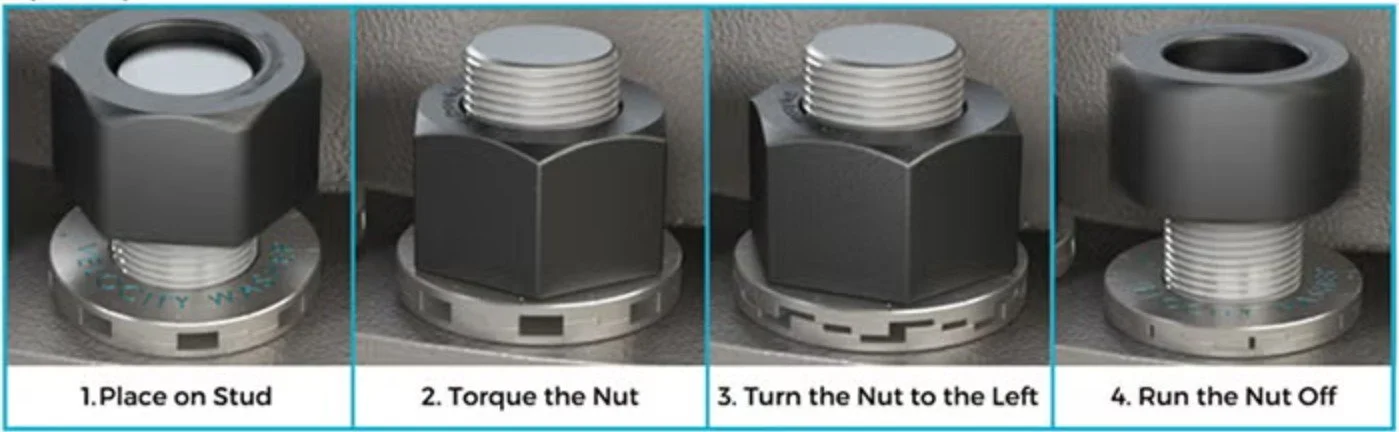

What is a Velocity Washer? It’s a specially engineered washer that is installed under the nut of a bolt (in place of a standard flat washer). At first glance, it looks like a slightly thicker, hardened washer with steps in it. The magic, however, lies in its ability to disengage the bolt load on command. In practice, when you need to loosen the bolt, you turn the nut just a small fraction of a turn (about 12 degrees) and the Velocity Washer “pops” – effectively unloading the tension in the bolt. With the clamping force gone, the nut can be spun off freely by hand or with minimal effort. In other words, the washer serves as a mechanical release mechanism, so that the high friction between threads (which causes galling or seizing) is eliminated before you unscrew the nut.

How does this help? The most immediate benefit is speed. Traditional bolt breakout (loosening) can be slow and uncertain – you might fight each nut all the way off the bolt, especially if threads are corroded or prone to gall. In contrast, with Velocity Washers, once you initiate that release, the nut encounters virtually no resistance. Field reports have shown that disassembly times for bolted joints can be 10x to 30x faster using this technology. For instance, a heat exchanger channel head that used to require multiple shifts of labor to unbolt was opened in a matter of hours when equipped with Velocity Washers. In one case study, a large flange with 32 bolts that normally took days to disassemble (often requiring torch cutting) was broken apart in roughly 1/20th of the time using this washer system. Faster disassembly directly translates to shorter turnarounds and less unplanned downtime.

Eliminating Galling: Because the Velocity Washer removes the load before turning the nut, it essentially prevents galling from happening. Galling occurs under high friction and pressure – exactly what is relieved by the washer’s mechanism. Maintenance teams that have adopted this technology report a 100% elimination of galling on critical bolts. No more seized nuts means no more surprise stuck bolts that derail the schedule. By changing something as simple as the washer, they avoid the scenario of having to cut off ruined fasteners or replace damaged studs. It’s a preventative approach: rather than dealing with galling after it happens, the washer stops it from happening in the first place.

Safety Improvements: The Velocity Washer also brings significant safety benefits. When nuts come off easily, workers spend far less time applying heavy force or using dangerous tools. The need for hot bolting (single stud replacement on live equipment) can be greatly reduced or eliminated, because bolts can be confidently removed during the planned shutdown without fear they’ll seize. This avoids the risky practice of swapping bolts while equipment is running just to ensure they’ll come out later. Moreover, since you’re not reaching for the grinder or torch nearly as often, you cut down on hot work hours. Less hot work means lower fire risk and less exposure of personnel to those hazards. In effect, the washer turns bolting into a quick, controlled activity rather than a strenuous, uncertain one. Crews can maintain better ergonomics (no more standing on a breaker bar for minutes on end) and they encounter fewer surprise lurches and slips. Another safety plus: because the technology makes bolt removal predictable, there’s less temptation to “hurry up” under pressure. Workers know the nut will come off cleanly, so they can focus on following the proper procedure instead of improvising or taking risky shortcuts to deal with a stuck bolt.

Operational Confidence: An often overlooked benefit of innovations like this is the confidence it gives to planners and engineers. If you know that critical joints will open without a hitch, you can plan your turnaround with more certainty and tighter timelines. Planners have reported that with Velocity Washers in place, they can shave off contingency time that was previously allotted for wrestling with old bolts. This means a leaner, more efficient maintenance schedule. It also means you can reliably reuse bolts and nuts that come off (since they aren’t being destroyed by galling or cutting), which can save costs on material and also time – no need to waste time finding replacement studs because the originals are fine. Technicians also appreciate when their tools work as intended: breaking loose a nut with a 12-degree turn and then zipping it off is a satisfying experience compared to fighting for every millimeter of thread. That morale and confidence can have subtle positive effects on how the maintenance work progresses overall.

Real-World Adoption: The Velocity Washer is not just a prototype in a lab; it’s been implemented in real industrial turnarounds. According to its developers, it has amassed over 100 million hours of successful use across global installations. For example, a major petrochemical plant in the U.S. used these washers on large heat exchanger flange bolts and reported saving on the order of 112 hours of production time by avoiding bolt-related delays. A Canadian oil refinery documented a 94% reduction in disassembly time on a reactor vessel after switching to Velocity Washers – what used to be a painstaking, multi-day bolt removal became a quick, routine job with no hot work required. Importantly, these washers have passed rigorous vibration and load tests (meeting military standards for vibration resistance and handling high loads without issues), so they are proven to hold up in high-stress service just like conventional hardware. They simply add an extra function when it comes time to disassemble.

It’s worth noting that the Velocity Washer is one example of emerging technology in the bolting arena. There are also improved bolting tools (like more precise hydraulic torque and tension devices), better gasket designs, and digital bolt load monitoring systems on the rise. All share the goal of making bolted joints more reliable and maintenance-friendly. But the simplicity of a washer that you can drop into existing procedures with no special training or tools makes the Velocity Washer particularly attractive. Maintenance managers and turnaround planners who have struggled with bolting issues are quickly recognizing that investing in such technology is far cheaper than paying for even a few extra hours of downtime.

Conclusion: Bolting Reliability – Key to Turnaround Success

From the initial shutdown to the final startup, the integrity of bolted joints plays a pivotal role in how smoothly a plant turnaround progresses. Bolt failures due to galling, overtightening, corrosion, and other mechanisms have historically been a thorn in the side of maintenance projects – causing leaks, safety incidents, delays, and inflated costs. As we’ve discussed, the consequences of a “small” bolting issue can spiral into big problems that affect an entire operation.

The good news for engineers and maintenance managers is that knowledge and technology are catching up to the bolting challenge. By understanding typical failure modes, teams can take preventative measures (proper torque control, use of anti-seize, routine bolt inspections, etc.) to reduce the risk. More importantly, innovative solutions like the Velocity Washer are changing the game by removing the root causes of common bolting failures. These tools allow critical maintenance work to proceed without the usual hiccups, making turnarounds more predictable and safe.

In a professional environment where every hour of downtime counts and every incident is scrutinized, focusing on bolting reliability yields significant returns. Think of each bolted joint as a gatekeeper in the journey from shutdown to startup: if all gates open and close smoothly, the journey stays on schedule. By investing in better bolting practices and advanced technology, industries can ensure that bolts remain a backbone of reliability rather than a single point of failure. The result is not only cost savings and schedule assurance, but also a safer workplace. In the end, attention to something as seemingly mundane as washers and nuts can make the difference between a turnaround that’s a success story and one that becomes a cautionary tale.

Every plant shutdown aims to eventually become a startup again – and when that transition is seamless, you often have smart bolting strategy to thank. The next time you plan a turnaround, remember that bolts may be small, but their impact is huge. Treat them with the respect, tools, and technology they deserve, and you’ll be one step closer to a flawless shutdown-to-startup execution.

_____

Disclaimer:

Portions of this article were generated with the assistance of ChatGPT, a large language model developed by OpenAI. The content is provided for informational purposes only and does not constitute professional, legal, financial, or academic advice. The views expressed do not necessarily reflect those of the author, and readers are encouraged to independently verify any information presented.

The AI-generated content has been reviewed and edited for clarity and accuracy where appropriate.