Velocity Washer®.

Eliminate galling. Increase production. Improve safety.

Eliminate Galling

Velocity Washer has a 100% success rate across all global installs in preventing galling.

Maximize Asset Uptime

Get your assets back to profitable production faster - just by changing your washer.

Lower Labor & Tool Costs

Eliminate the need for specialized service providers - no more galling headaches.

Guaranteed Time Savings

100% confidence that things will get disassembled on time, every time.

No Issue With Vibration

Engineered to meet military standards (MIL-STD-167-1A, MIL-S-901D, and MIL-STD-1312-7A).

No Special Tools

Use your same bolting procedures and loads. Turn the nut 12° and the magic happens.

How to prevent galling in one minute.

Watch this one minute video to get an overall perspective of what Velocity Washer - the original mechanical release washer - can do for your operations. Hint: You’ll have 100% elimination of galling across all your critical flanges.

How does it work?

Watch this 11-second video to see how the technology functions. Pretty simple, right?

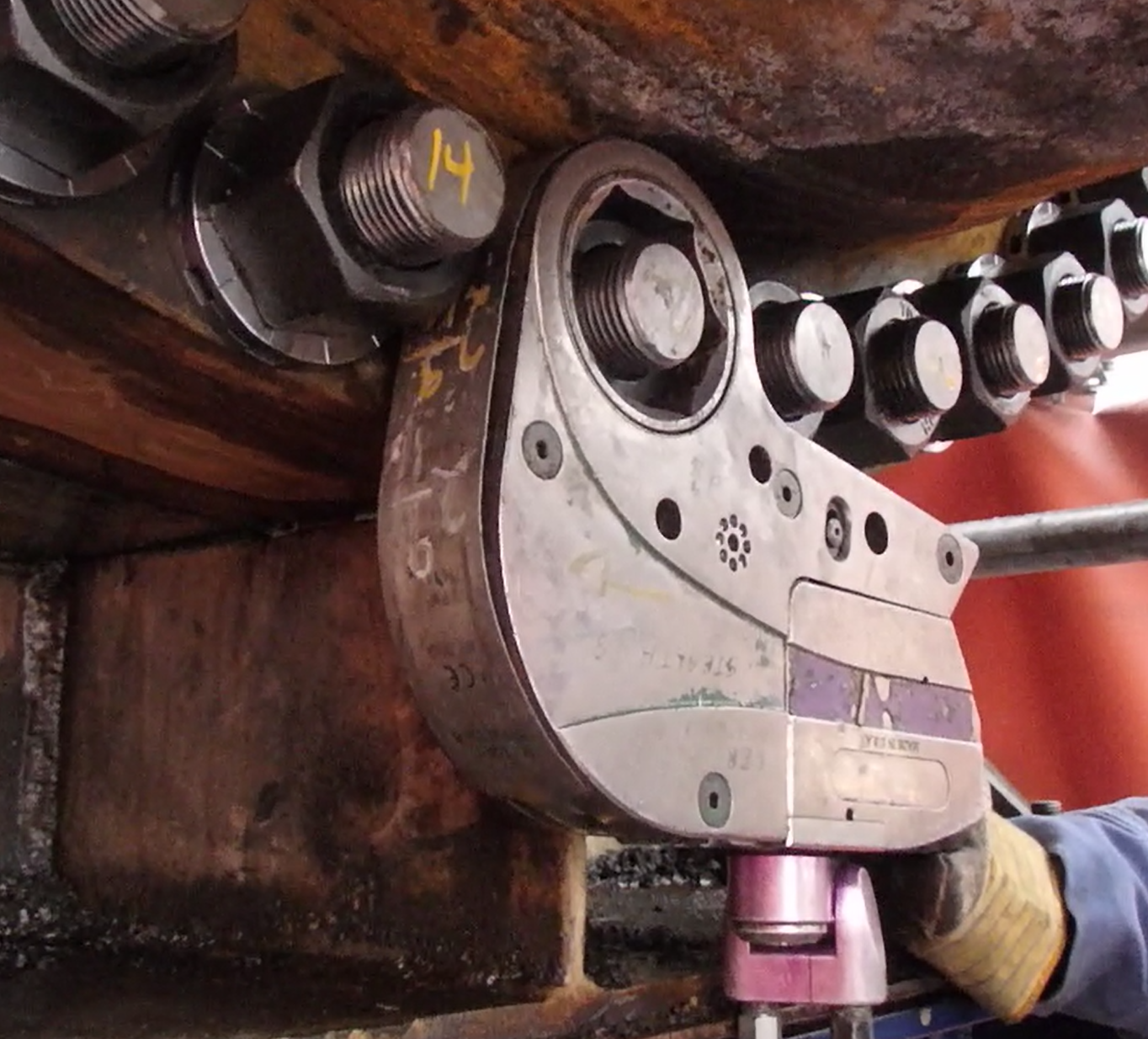

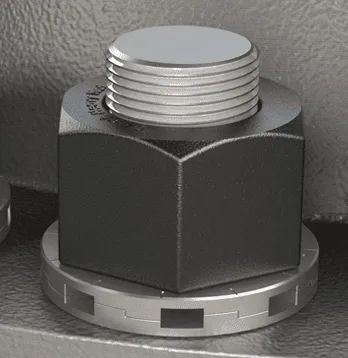

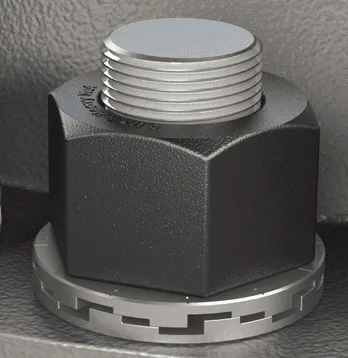

1. To install, simply place the Velocity Washer on the stud. Due to its symmetric design, it can’t be installed in the wrong orientation, delivering the simplest installation.

2. You then torque the nut on using standard procedures: there are no special tools.

3. As always, turn the nut to the left. It will take less than one stroke of the torque wrench for the Velocity Washer to release all load.

4. Once the Velocity Washer pops, all load will be removed, allowing the nut to be easily run off.

The proof is in the numbers.

This data is all customer supplied and based on usage of Velocity Washer. The most important takeaway: all this value is gained from simply changing a washer (and nothing else, including bolting procedures).

Case Study #1: 112 Hours of Increased Production

Case Study #2: 94% Faster Disassembly

Engineered for precision. Trusted for performance.

Each Velocity Washer is individually precision CNC machined to give you the highest degree of safety and efficiency when disassembling your critical bolting assets.

Standard Velocity Washers are precision-cut from 4140 HT, a durable low-alloy steel that meets the performance needs of most industrial applications.

For specialized environments, we also offer Velocity Washers in a range of exotic materials, including multiple grades of stainless steel (such as 316), Inconel, and other alloys tailored to your requirements.

What People Are Saying

“We have the Velocity Washers on two of our blowdown exchangers. We typically have to torch cut these large studs; with the Velocity Washers they spun off just like shown on the promotional videos. We reused the studs and nuts.”

– Lead Reliability Engineer

★★★★★

“The same reactor head after installation of Velocity Washers, took only 1-2 hours in total to disassemble, with no damage to capital equipment, no hot work needed and no studs needed replacing.”

– Turnaround Planner

★★★★★

“Our results with the Velocity Washers were very good. Normally we would budget four 10 hour shifts of gouging. This involved a substantial hoarding and of course time. With the Velocity Washers it took us a bit over half a shift.”

– Maintenance Coordinator

★★★★★

Our Technology is Trusted by

MIL-SPEC Vibration Resistance

Velocity Washer has passed three MIL-SPEC standards for vibration and shock resistance (MIL-STD-167-1A, MIL-S-901D, and MIL-STD-1312-7A).

In this video, you can watch the test block get chewed up - shavings flying and all - while the Velocity Washers hold strong without a hint of wear or unintended activation.

FAQs

-

Velocity Washer sizes range from 3/4” – 5” bolt diameter. Contact us for sizes outside this range.

-

No vibration issues. We have passed MIL-STD-167-1A, MIL-S-901D (Shock), and MIL-STD-1312-7A. For example, the Velocity Washers have been tested over 30,000 cycles, applying 30 G acceleration and 15,400lbs of shaker force. Search for our proof video on YouTube.

-

No, the Velocity Washers are designed to replace a standard hardened washer, so no additional tooling is needed.

-

No, you only use one Velocity Washer per stud on the same side of the flange the torque wrench will be applied.

-

The Velocity Washers need less torque to turn than a standard bolt, so no additional torque is needed.

-

Velocity Washers will fit wherever a standard washer will fit.

-

Velocity Washers are typically double the height of a standard washer. We have a full spec sheet available on request.

-

Velocity Washers are typically designed to relieve 0.12” of bolt stretch. That is equivalent to 100% bolt yield on a 34” grip length.

-

The load-bearing area of the Velocity Washer is greater than that of the bolt, and it is made from a stronger material. So, anything the bolt can take, the Velocity Washer can take.

-

The max temp is around 850F. If we have an application that goes above 850F, we have other alloys that can take that max temperature up to 1100F safely.

-

Standard Velocity Washers are made from HT4140 which has been heat-treated and stress relieved. In special circumstances, we can cut Velocity Washers in different materials based on your specific needs.

-

Velocity Washers are made from HT4140, which is equal or stronger material than standard bolts. You will yield the stud before you damage the Velocity Washers.

-

Yes, NACE explicitly states that there is no H2S stress corrosion cracking concerns for components in pure compression, like Velocity Washer.

-

Some people refer to the Velocity Washer as a “mechanical release washer”. Whatever you call it, Velocity Bolting has the patent on the technology and we’re pleased to be the exclusive supplier of Velocity Washer through our network of distributors.

-

Specifications available upon request, including material, hardness, outer diameter, height, activation displacement, activation rotation, stress area, washer-to-bolt area ratio, maximum bolt load, maximum bolt stress and max grip length at max load. E-mail us at info@velocitybolting.com and we’ll send them along.